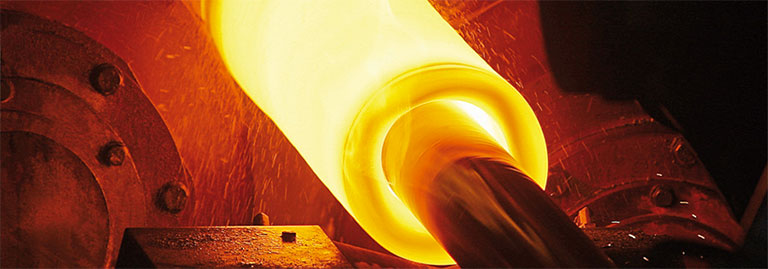

Embedded within the Mannesmann Precision Tubes Group, the Zeithain plant operated by Mannesmannröhren-Werk GmbH makes seamless hot-rolled steel tubes (hollows and tubes finished to size). These are either sent on to the cold drawing mills of the Group or are sold directly to external customers.

Our plant in Saxony is one of the most efficient producers of small-size seamless tubes in the market and also operates Europe's most state-of-the-art push bench facility.

General contact

Mannesmannröhren-Werk GmbH

Mannesmannstrasse 11

01619 Zeithain

Germany

+49 3525 79-0

info.mrw@mannesmann.com

Sales contact

Felix Harms

Key Account Manager

Mannesmann Precision Tubes

Wiesenstrasse 36

45473 Mülheim an der Ruhr

Germany

+49 208 458-1616

felix.harms@mannesmann.com

Dimensions

Hollows | ||

| Outside diameter | 17.2 - 133 mm | 0.677 - 5.236'' |

| Wall thickness | 2 - 20 mm | 0.079 - 0.787'' |

| Length | up to 22 m | up to 72.2' |

Finished tubes | ||

| Outside diameter | 17.2 - 133 mm | 0.677 - 5.236'' |

| Wall thickness | 2 - 20 mm | 0.079 - 0.787'' |

| Length | up to 22 m | up to 72.2' |

| Other dimensions on request | ||

Our tubes are distributed by Mannesmann Precision Tubes. Further information about our products and the contact information for your inquiry can be found here.

Application areas

Energy

- Tubes for apparatus and container construction

- Boiler tubes up to 22.5m (73.9 ft) lenght for power plants

- Linepipes

- Heat exchanger tubes

- Boiler and pressure vessel construction

- Oil and gas linepipes

- High-pressure tubes for chemical plants

- Structural hollows for steel construction, bridge construction and crane construction

History

Steel tubes production has a long tradition in Saxony, starting in 1907 with the commissioning of the first rolling mill for the first mill for seamless tubes in Riesa. In May 1961, the groundbreakig for the new tube of the VEB Stahl- und Walzwerk Riesa took place in Zeithain.

In 1965, the first hot-rolling mill, Tube Mill III (Plug MIll), went into operation, which was decommissioned in 1990. The second hot-rolling mill , Tube Mill IV (Push Bench), was built in 1978. Mannesmannröhren-Werke Sachsen GmbH, Zeithain, was founded in 1991 as a wholly owned subsidiary of Mannesmannröhren-Werke AG, Mülheim an der Ruhr. Since this aquisition considerable investments have been made in the plant technology of the Tube Mill IV. These investments were focused mainly on modernizing computer technology to improve the process control of the equipment.

The previous piercing press in Zeithain had been replaced by the combination of a Three-Roll Piercing Elongating mill (TPE) with the existing push bench went into operation in February 2008.

| 1961 | Groundbreaking of Tube Mill III, VEB Steel und Rolling Mill Riesa in Zeithain |

| 1965 | Commissioning of Tube Mill III (Plug Mill) |

| 1978 | Commissioning of Tube Mill IV (Push Bench) |

| 1991 | Mannesmannröhren Werke Sachsen GmbH is formed and takes over the Zeithain Tube Mill as part of Mannesmannröhren-Werke AG |

| 1997 | Mannesmannröhren Werke Sachsen GmbH merges with Mannesmann-Warmrohr GmbH; Mannesmann-Warmrohr GmbH is contributed to the Vallourec & Mannesmann Tubes joint venture |

| 2007 | Salzgitter Group takes over the Zeithain Tube Mill. Newly formed Salzgitter Mannesmann Rohr Sachsen GmbH takes over the ring manufacturing division from Mannesmannring Sachsen GmbH, part of the Salzgitter Group since 2000 |

| 2017 | Rebranding of Salzgitter Mannesmann Precision GmbH to Mannesmann Precision Tubes GmbH and Salzgitter Mannesmann Rohr Sachsen GmbH to Mannesmannröhren-Werk GmbH |